STORAGE

- Maximum storage temperature: 90°F

- Store rolls laying on the side (one edge of tape)

- Maximum humidity: 80%*

APPLICATION - Manual and Machine Application

- The surface must be clean & dry. If needed, clean the surface with 90% Isopropyl Alcohol.

- Tape dispensing speed is typically 12 inches / second. Faster speeds are possible, but may activate the hidden VOID OPENED pattern.

- When applying tape, observe the minimum surface temperature listed in “Choosing Your Security Tape” section on our website:

- EST-36 and EFT/PFT tapes with hot melt adhesive +40°F

- PST/EST tapes with acrylic adhesive – as low as +30°F

- PVT/EVT tapes with acrylic adhesive – as low as +20°F

- Apply the security tape directly to the intended surface. Do not apply on top of other packing tape.

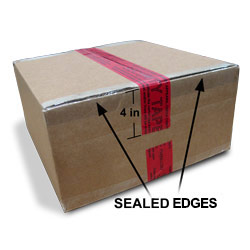

- When sealing cartons, seal the opposing flaps on the top and extend the tape a minimum of 4 inches down each side of the box. Repeat this process for the bottom seam of the carton.

![Sealing carton]()

- If the cartons have excess 'spring' in the flaps, after applying the security tape on the flaps, use standard carton sealing tape to seal the edges of the flaps to the side of the box. Other options are to glue or staple the flaps closed before applying the security tape. Repeat this process for the top and bottom of the carton.

![Sealing carton]()

- Only apply security tape in a single layer. Do not apply security tape on top of other security tape.

- On the recommended surfaces at 70°F, the tamper evident feature should be functional within 1 minute of application. Other surfaces may require more curing time. If the tamper evident feature does not perform immediately, more curing time usually improves the performance of the tamper evident feature.

- The various tape formulations we offer perform differently depending on the material surface and application conditions. We recommend testing tape samples under actual end-use conditions to confirm compatitibity with your specific application. We offer free samples for testing.

- See our trouble shooting guide for any other issues, or contact us.

Additional Instructions for Tape Application Machines

Our security tapes are designed to show tamper evidence more easily, which can create processing issues with some tape machines. Therefore, we recommend testing a sample roll (minimum 180 LF) tape before placing an order to confirm if your tape machine rollers require a modification and to confirm if the tape application speed meets your production needs.

Machine Rollers: We recommend textured and plasma-treated rollers for any machine rollers which are in direct contact with the adhesive side of the tape. Without the special surface treatment, the rollers may trigger the hidden security message and/or adhesive may accumulate on the machine rollers which contact the tape adhesive. This issue is more prevalent with our EVT/PVT and EFT/PVT tapes. If your machine rollers cannot be modified by the tape machine manufacturer, please give us a call for other options.

Application speed: The maximum application speed depends partly on the tape type (EST/PST will dispense faster) and partly on the tape age (tapes over 2 years old may require lower dispensing speeds).

* For improved shelf life in high humidity conditions, place the stored tape in a plastic bag when humidity is less than 80%. Seal the bag for storage. Open the bag to remove additional rolls as needed and reseal the bag. A twist tie on the bag will provide a sufficient seal.